On 05/31 the the grup did the first test launch, with a wing of the first deliverable. The test was in the ground because the access to the CIMATEC 4 was blocked. After the test, we realized a lot of changes to be made in our production of our glider, until material changes used. Even this being only a test glider, helped in the evolution of grup's knowledge regarding the construction of the model airplane. Below is a video of one of the releases made by the grup.

sexta-feira, 31 de maio de 2019

9ª semana

No dia 31/05 foi feito o primeiro teste de lançamento, com a asa do primeiro entregável. O teste foi feito do solo pelo fato de que o acesso até o ultimo andar do CIMATEC 4 estava bloqueado. Após o teste percebemos diversas mudanças a serem feitas no produção do nosso planador, até mudanças quanto aos materiais utilizados. Mesmo esse sendo somente um planador de teste ajudou na evolução do conhecimento da equipe quanto a construção do aeromodelo. Segue abaixo um vídeo de um dos lançamentos feitos pela equipe.

On 05/31 the the grup did the first test launch, with a wing of the first deliverable. The test was in the ground because the access to the CIMATEC 4 was blocked. After the test, we realized a lot of changes to be made in our production of our glider, until material changes used. Even this being only a test glider, helped in the evolution of grup's knowledge regarding the construction of the model airplane. Below is a video of one of the releases made by the grup.

On 05/31 the the grup did the first test launch, with a wing of the first deliverable. The test was in the ground because the access to the CIMATEC 4 was blocked. After the test, we realized a lot of changes to be made in our production of our glider, until material changes used. Even this being only a test glider, helped in the evolution of grup's knowledge regarding the construction of the model airplane. Below is a video of one of the releases made by the grup.

sábado, 25 de maio de 2019

The technical term for this week: empennage

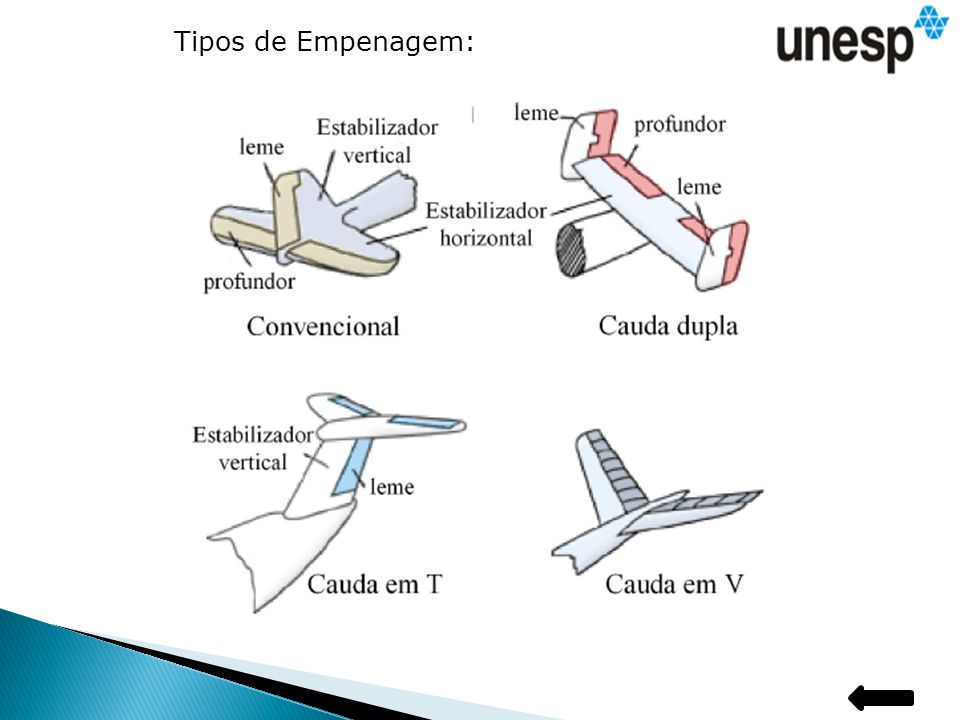

The empennage is a structure of the airplane consisting of the fuselage end part and the vertical stabilizers (steering rudder that guides the aircraft to the left or right), and horizontal (up or down movement controller). The joint composed by the fuselage of an aircraft comprises the wings and the empenagem. The empennage is the part located in the rear region being responsible for the longitudinal and directional stability of the airplane.

It is composed by the elevators, responsible for the pitching movements, which are to go up (to climb) and to prick (down) and the rudder responsible for the yaw movements that are swerved to the right and turned to the left.

|

| source: https://slideplayer.com.br/slide/1265377/ |

8ª semana

A oitava semana da equipe teve a construção do primeiro protótipo do planador. Utilizamos isopor cortado e lixado, o mais próximo possível do perfil, para preencher o espaço entre as nervuras das bordas de ataque e de fuga da asa e da empenagem, porque deste modo não perderíamos tanto perfil aerodinâmico e o revestimento com vinil seria feito de forma mais fácil e rápida.

Após feito o preenchimento, foi iniciada a etapa de revestimento com o vinil, e o esboço de um corpo para fixação da asa e da empenagem. Utilizamos um tubo de papelão como corpo, e isopor lixado de forma esférica como bico. A fixação foi feita com cola e durepoxi.

The eighth week of the team had the construction of the first prototype of the glider. We use cut and sanded Styrofoam as close as possible to the profile to fill the space between the leading and trailing edges of the wing and empennage because this would not lose so much aerodynamic profile and the vinyl coating would be made in a way easier and faster. After filling, the coating step with the vinyl was started, and the sketch of a body for fixing the wing and empennage. We use a cardboard tube as a body, and styrofoam sanded as a beak. Fixation was done with glue and durepoxy.

|

| Fonte: própria |

|

| Fonte: própria |

|

| Fonte: própria |

|

| Fonte: própria |

The eighth week of the team had the construction of the first prototype of the glider. We use cut and sanded Styrofoam as close as possible to the profile to fill the space between the leading and trailing edges of the wing and empennage because this would not lose so much aerodynamic profile and the vinyl coating would be made in a way easier and faster. After filling, the coating step with the vinyl was started, and the sketch of a body for fixing the wing and empennage. We use a cardboard tube as a body, and styrofoam sanded as a beak. Fixation was done with glue and durepoxy.

domingo, 12 de maio de 2019

The technical term for this week: truss

Truss is a term used in structural engineering that uses triangular shapes and knots (triangle vertex) to make the structure more stable, in addition to being lighter structures they are made so that all force on the lattice is placed on top of these nodes so eliminating bending and twisting efforts.

|

| Source: repositorio.roca.utfpr.edu.br/jspui/bitstream/1/7341/1/PB_DAMEC_2016_2_29.pdf |

|

| Source: br.pinterest.com/pin/296111744230072285/?lp=true |

7ª semana

Na sétima semana começamos a estudar como fazer a fuselagem da forma mais estável e resistente possível contudo sem acrescentar demasiado peso ao planador, partindo disso iniciamos a pesquisa por materiais resistentes e leves para serem colocados no projeto e estudamos a possibilidades de colocar treliças para assim manter o planador leve e resistente.

In the seventh week we began to study how to make the fuselage in the most stable and resistant way possible without adding too much weight to the glider, starting from that we started the search for resistant and light materials to be placed in the project and we studied the possibilities of placing trusses in order to maintain the light and tough glider.

domingo, 5 de maio de 2019

The technical term for this week: Drag

Drag is a mechanical force acting opposite to the relative motion of any object moving with respect to a surrounding fluid.The drag which is responsable for the redution of the object's speed can exist between two fluid layers (or surfaces) or a fluid and a solid surface, the drag is generated by the diference of presure, which, in the case of an airplane, is generated by the diference in the velocity between the fluid and the solid object. Unlike other resistive forces, such as dry friction, which are nearly independent of velocity, drag forces depend on velocity. Drag force is proportional to the velocity for a laminar flow and the squared velocity for a turbulent flow. Even though the ultimate cause of a drag is viscous friction, the turbulent drag is independent of viscosity. The drag is a mechanical force that is generated by the diference of presure, which, in the case of an airplane, is generated by the diference in the velocity between the fluid and the solid object.

|

| Source:aeronotes.weebly.com/types-of-drag.html |

6ª semana

A sexta semana se iniciou com o recebimento da medeira balsa, material que seria utilizado para a construção da estrutura da asa da primeira entrega. Por conta de um engano na avaliação das dimensões do material, foi visto q n seria possível construir a asa com as dimensões planejadas anteriormente, por conta disso elas foram reduzidas pela metade. A equipe iniciou a construção da asa na quinta-feira pela manhã e devida a experiencia de construção com a madeira balsa, foi percebido que ela poderia ser mais frágil do que a equipe imaginou. Por conta disso, a equipe fez algumas pesquisas e decidiu que as longarinas, que sofreriam maior esforço de flexão deveriam ser feito de outro material. Por fim, após a construção estar finalizada a asa foi pesada no laboratório de física. foi obtido um peso de 83,80g.

|

| Fonte: Própria |

The sixth week began with the receipt of balsa wood, material that would be used for the construction of the wing structure of the first delivery. Due to a mistake in the evaluation of the dimensions of the material, it was seen that it was not possible to construct the wing with the dimensions previously planned, because of this they were reduced by half. The team started building the wing on Thursday morning and due to the experience of building with the raft wood, it was realized that it could be more fragile than the team imagined. Because of this, the team did some research and decided that the stringers, which would undergo more flexing effort, should be made of other material. Finally, after the construction was finished, the wing was weighed in the physics laboratory. a weight of 83.80 g was obtained.

|

| Source: Own |

Assinar:

Postagens (Atom)